Introduction

In the fiercely competitive world of metal manufacturing, operational efficiency, precision, and cost control are paramount. Traditional systems often fall short in integrating production, inventory, and financial processes, leading to inefficiencies. That’s where ERPNext, a powerful open-source ERP software, steps in to transform metal manufacturing operations.

With a suite of scalable and customizable ERPNext services, metal manufacturers can now streamline their operations, from procurement to production and dispatch. In this article, we explore why ERPNext manufacturing is the ideal solution for modern metal manufacturing companies.

Why Metal Manufacturers Need ERP

Before diving into the features of ERPNext, let’s understand the challenges metal manufacturers face:

- Complex Bill of Materials (BOM)

- Inventory mismanagement

- Real-time production tracking difficulties

- Quality control lapses

- Manual, error-prone workflows

- Lack of integration between departments

These challenges can seriously affect productivity and profitability. A robust ERP software like ERPNext helps eliminate these roadblocks.

Key Features of ERPNext for Metal Manufacturing

1. Advanced Bill of Materials (BOM) Management

Metal manufacturing often involves multi-level BOMs. ERPNext enables detailed BOM structuring with:

- Nested BOM support

- Real-time cost tracking

- Workstation assignment

- Multi-variant production planning

This empowers production teams to execute jobs accurately and within budget.

2. Real-Time Production Planning

With ERPNext manufacturing, you get:

- Machine-wise job allocation

- Work order scheduling

- Capacity planning

- Gantt chart-based visual timelines

Manufacturers can easily identify bottlenecks and reschedule tasks with a drag-and-drop interface.

3. Inventory and Warehouse Management

Metal parts and raw materials require precise inventory tracking. ERPNext provides:

- Real-time stock visibility

- Automated stock reordering

- Serialized and batch-wise tracking

- Multi-warehouse management

This helps reduce stock-outs and overstocking while improving operational transparency.

4. Shop Floor and Workstation Efficiency

ERPNext connects the shop floor directly with your ERP system, allowing:

- Workstation-level production monitoring

- Downtime logging

- Labor and machine performance reports

- Real-time updates via IoT integrations

This ensures maximum equipment utilization and lean manufacturing.

5. Quality Control at Every Stage

Whether it’s raw material testing or final product inspection, ERPNext supports:

- Quality Inspection Templates

- Rejection and scrap analysis

- Defect tracking and resolution workflows

- Audit trails for compliance

Such quality-first operations improve customer satisfaction and reduce wastage.

Integrations That Scale Your Operations

ERPNext doesn’t just stop at manufacturing. It integrates seamlessly with:

Purchase and Procurement: Automate RFQs, supplier quotes, and PO generation.

- Sales and CRM: Manage quotations, orders, and customer communication in one place.

- Finance and Accounting: Real-time sync with ledgers, payment entries, and tax reports.

- HRMS: Handle payroll, shifts, and attendance for production staff.

This makes ERPNext a full-stack ERP software solution for the metal industry.

Benefits of Choosing ERPNext Services for Metal Manufacturing

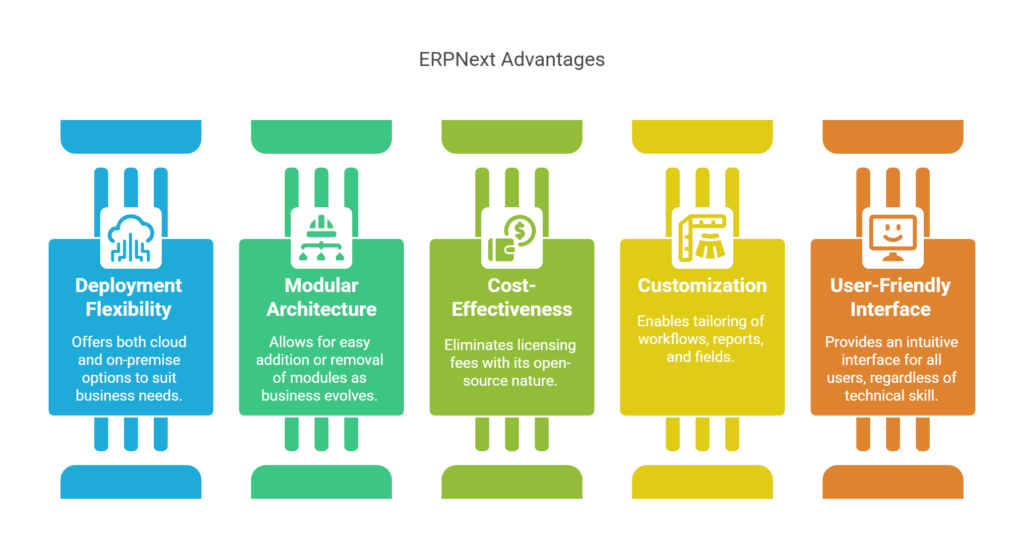

Here’s what makes ERPNext services the go-to choice for forward-thinking manufacturers

Real-World Use Case

A mid-sized metal fabrication unit in India adopted ERPNext to consolidate their siloed departments. With the ERPNext manufacturing module, they achieved:

- 25% reduction in production delays

- 40% improvement in inventory accuracy

- 30% cost savings in administrative overhead

This transformation was made possible through tailored ERPNext services, enabling smooth onboarding and custom workflows for the client’s unique needs.

How to Implement ERPNext for Your Metal Manufacturing Business

Implementing ERPNext involves the following steps:

- Requirement Analysis: Identify pain points and goals.

- System Design: Define workflows, BOMs, and user roles.

- Customization: Use Frappe framework for module-level changes.

- Training: Equip staff with hands-on experience.

- Go Live & Support: Launch and continuously monitor performance.

Engaging with an experienced ERPNext service provider ensures smooth implementation and minimal downtime.

Conclusion

Metal manufacturing demands precision, speed, and adaptability — qualities that ERPNext manufacturing delivers through its robust, modular, and cost-effective design. With expert ERPNext services, businesses can automate critical functions, streamline workflows, and stay ahead of the competition.